10+ kerf bending calculator

On calculators with Slider Controls drag slider tab to get close then use keyboard cursor keys to fine tune. This increases the kerf of the cut and causes dimensional inaccuracies.

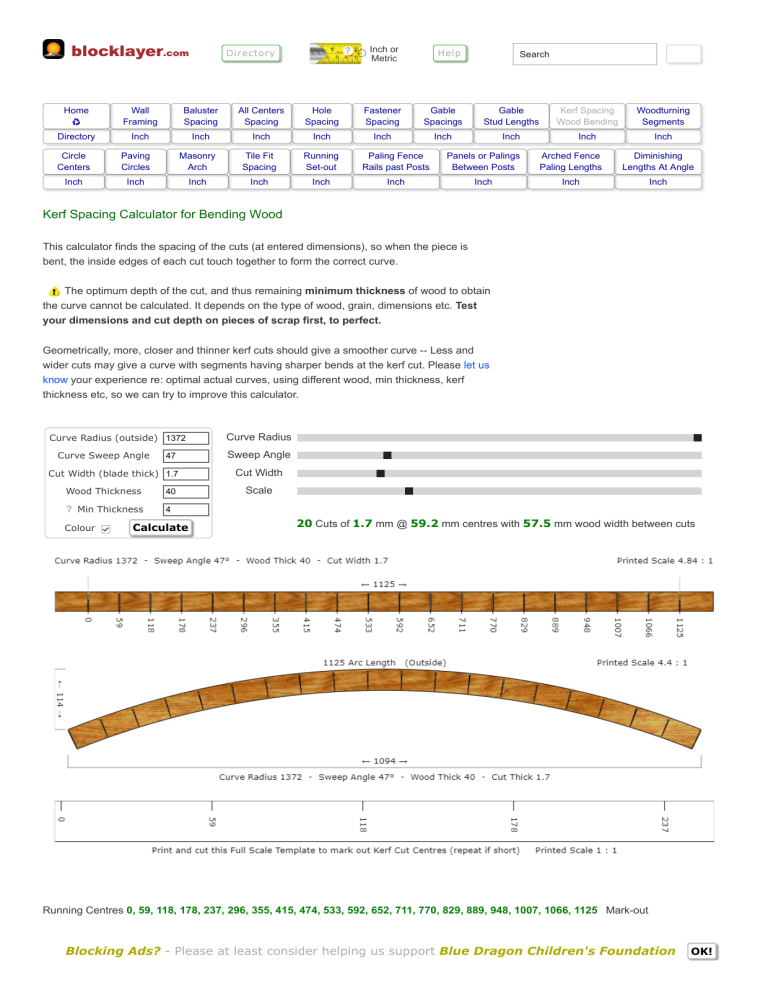

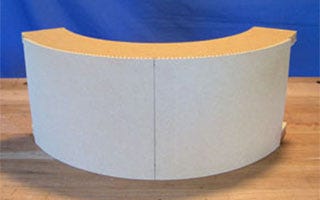

Kerf Spacing Calculator For Bending Wood Metric

Results for Fiberglass Ductboard Tools Edison NJ.

. On calculators with Slider Controls drag slider tab to get close then use keyboard cursor keys to fine tune. At Hubs the recommended sheet metal thickness range is between 05-10 mm 002-0394 in for laser cutting and 05-6 mm 002-0236 in for bending. M 2 Therefore the SI unit of bending stiffness is Nm².

Or Right Click the slider and use the up down arrows that appear to adjust - Right click again to go back to the slider. The bending moment varies over the height of the cross section according to the flexure formula below. On calculators with Slider Controls drag slider tab to get close then use keyboard cursor keys to fine tune.

Sheet Metal Bending Calculator. Add fillets to the corners to create a smooth finish. Share this Calculation The best way to see how this works is just drag all the sliders and check - uncheck all the boxes and watch the diagram and results change.

The best way to ensure quick and simple sheet metal bending is to follow our bending and. Unlike conventional milling the wire cuts by melting the plastic surrounding it and when the wire stays in one position for some time the surrounding material keeps melting away. Bending stiffness E I N m2 m4 N m 2 m 4 Nm2 N.

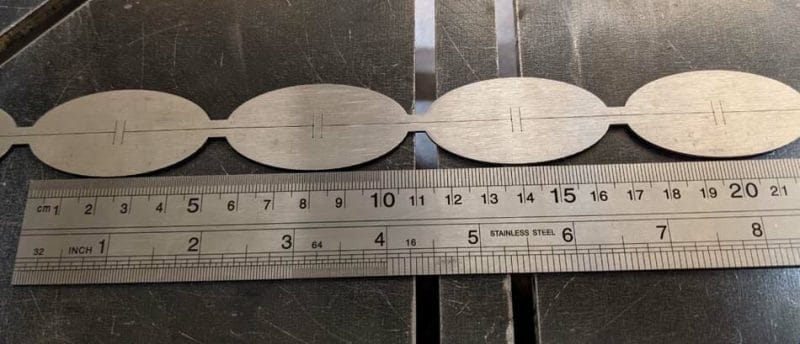

Design best practices for laser cutting. Is the cut acceptable at the slower speedsupper limits of the thickness for performance of each wattage. Am wondering about the kerf.

4 The beam of optical fiber laser transmit along the optical fiber without external reflected light path system saving the cost of reflection lens the organ shield without external optical path adjustment avoid the light path pollution by dirt but. Raleigh NCProperly connecting and sealing the rigid foam board duct are two of the most important tasks for any ductwork installation. SendCutSend offers a number of high-quality materials in various thicknesses for bending.

8 8 16 16 8 8 12 Last top gap will be calculated. Metric Deck Floor Board Spacing Gap Calculator - Quantities Carpentry Woodworking Metric Kerf Spacing Calculator for Bending Wood - with Templates Metric Segmented Turning Calculator Metric Hub and Spoke Printable Templates - Model Wheels Metric Radial Center Join Templates - Full Scale Metric Dovetail Template Generator. 5052 Aluminum 040-125 Brass 040-125 Copper 063 and 125 Mild Steel 030-250 Bending can be tricky to design for but it doesnt have to be.

Or Right Click the slider and use the up down arrows that appear to adjust - Right click again to go back to the slider. IDM Members meetings for 2022 will be held from 12h45 to 14h30A zoom link or venue to be sent out before the time. It ensured the cutting quality consistency throughout the cutting width especially suitable for large-format laser processing system.

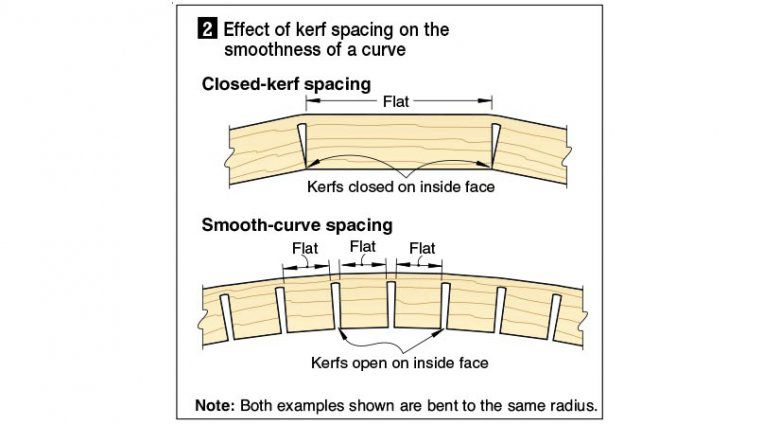

Optimal actual curves using different wood min thickness kerf thickness etc so we can try to improve this calculator. Calculate Kerf Spacing for bending wood With printable full scale set out templates. Geometrically more closer and thinner kerf cuts should give a smoother curve -- Less and wider cuts may give a curve with segments having sharper bends at the kerf cut.

There are two variables which affect the kerf of the cut. Use the Running set out lists to mark out member positions as these points are rounded as they go. Centers and Spacing results are rounded to nearest 132 so multiplying Space by number of spaces may not result in exact Total Length.

Enter Length Between End Posts Member Width and Gap Size to calculate required end gaps to maintain spacing. On calculators with Slider Controls drag slider tab to get close then use keyboard cursor keys to fine tune. Where M is the bending moment at the location of interest along the beams length I c is.

Wall Framing Calculator - Stud Spacing and Sheeting Fit. Kerf Spacing Wood Bending. Please let us know your experience re.

Optimal actual curves using different wood min thickness kerf thickness etc so we can try to improve this calculator. We also offer waterjet cutting and cnc routing. Shiplap or V-groove joints make for tighter connections.

Geometrically more closer and thinner kerf cuts should give a smoother curve -- Less and wider cuts may give a curve with segments having sharper bends at the kerf cut. Online Laser Cutting versus Waterjet Cutting and CNC Routing. With Exact Spacing if the 2nd to last member runs into the end member the 2 end members combine double membersDrag the Centres or Total Length slider to see the effect of double end members.

The Best Wainscoting Layout App. Use a combination of staples and special pressure-sensitive tape to secure and. Or Right Click the slider and use the up down arrows that appear to adjust - Right click again to go back to the slider.

Enter individual shelf gaps in inches bottom to top as comma separated values. October 26 2022 at 802 am. Calculate cutting dimensions and best fit for circular paving and fire pits with Full scale cutting templates - Metric.

Or Right Click the slider and use the up down arrows that appear to adjust - Right click again to go back to the slider. Press Brake Tonnage Calculator. If youre stuck with an end gap thats too small or double end members try Adjust Both Ends Equally to open and spread the gap to each end.

Running measurements are and on - From start of wall to near side of. Mark-out If you have multiple panels of un-equal length youll need to adjust the 2 end spacings on each panel to maintain correct spacing. Please let us know your experience re.

Die Blanking Flat parts and some parts with formed features may be manufactured complete in full automation or made ready for secondary semi-automated bending and forming processes. The good news is that we will always select the best machine for your project that will cut your parts with efficiency and at the most affordable rate. Dovetail Template Generator Print fold over end of wood and.

Put-and-Take Tooling Semi-complex dies actuated manually or by machine form complex features andor multiple bending operations in one step. Calculator Apps for Home Improvement Remodeling Construction and Renovation with Detailed Scaled Diagrams for all Construction Tasks Woodwork Metal Work and Craft.

Has Anyone Used Cc To Kerf Wood For Bending Shapeoko Carbide 3d Community Site

Exporting A Dxf From Solidworks With No Kerf Cuts

Kerf Bending Axiom Forum

Kerf Bending Axiom Forum

Bending Wood Part I Kerf Bending

Calculation Method Of V Grooving Machine Bending Krrass

Sheet Metal Bending Parameters Calculator Gasparini Industries

Kerf Bending Wood

Kerf Spacing Kerf Bending Derevoobrabotka Stolyarnye Raboty Pokraska Dereva

Ci Tonykim

Kerf Bending Plywood Finewoodworking

Kerf Spacing Calculator For Bending Wood Grasshopper Mcneel Forum

5 Kerf Bending Tips And Tricks For Beginners Guide To Kerf Bending Wood Youtube

Where S All The Cnc Kerf Bending Make

Power Tool Woodworking For Everyone Online Table Saw Special Operations

Fabacademy 2021 Final Project By Ismael Lb

Kerf Bending Axiom Forum